- info@originsysglobal.com

- Sun - Thu: 9:00 AM - 5:00 PM

We are creative, ambitious and ready for challenges! Hire Us

We are creative, ambitious and ready for challenges! Hire Us

Over 10 years we help companies reach their financial and branding goals. Engitech is a values-driven technology agency dedicated.

411 University St, Seattle, USA

engitech@oceanthemes.net

+1 -800-456-478-23

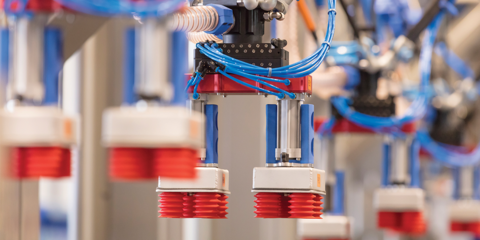

In today’s global marketplace, end-of-line automation can ensure the production of finished products for delivery to the distribution channel efficiently and cost-effectively.

Manufacturers are constantly looking for more progressive ways to make their end-of-line production more productive and time-saving.

That’s where automation comes in and makes the end-of-line process easier.

End-of-Line automation refers to automated technology that operates at the end of a production line to guarantee that the product is packed and prepared to deliver to the retailers, wholesalers, or market outlets.

Many businesses find it challenging to justify their end-of-line packaging automation at first. Still, after looking at how it will influence your production process, it becomes apparent that end-of-line automation is the ideal answer for any expanding company.

Machine length: 2000 mm

Machine width: 1250 mm

Machine height: 1760 mm

Machine frame: Aluminum - profile, Stainless steel

Cladding pannels/doors: Transparent / non-transparent: Polycarbonite

Weight: Approx. 900 KG

Noise level: 66 dB

Control cabinet: Integrated in machine

Working procedure: Servo / Pneumatic

Air pressure: 5-6 bar

Sealing method: Tape

Supply voltage: 220VAC

Output: Max. 6 cases / min

Machine length: 1680 mm

Machine width: 1100 mm

Machine height: 1760 mm

Machine frame: Aluminum - profile, Stainless steel

Cladding pannels/doors: Transparent / non-transparent: Polycarbonite

Weight: Approx. 700 KG

Control cabinet: Integrated in machine

Working procedure: Servo / Pneumatic

Supply voltage: 220VAC

Output: Max. 6 cases / min

Machine length: 1300 mm

Machine width: 1000 mm

Machine height: 2000 mm

Machine frame: Aluminum - profile, Stainless steel

Cladding pannels/doors: Transparent / non-transparent: Polycarbonite

Weight: Approx. 700 KG

Noise level: 66 dB

Control cabinet: Integrated in machine

Working procedure: Servo / Pneumatic

Air pressure: 5-6 bar

Sealing method: Tape

Supply voltage: 220VAC

Speed: 50 Bundle / min

Capacity: Max. 400 / min

Machine length: 2700 mm

Machine width: 2700 mm

Machine height: 2830 mm

Machine frame: Aluminum - profile, Stainless steel

Cladding pannels/doors: Transparent / non-transparent: Polycarbonite

Weight: Approx. 1100 KG

Control cabinet: Integrated in machine

Working procedure: Servo / Pneumatic

Supply voltage: 220VAC

Air pressure: 6 bar

Speed: 9 Max. strokes/1'